Extraction Equipment + Solvents

-

Ventana Plant Science Isopropyl Alcohol ISO 99.9% 1-Gallon *HAZ*

Vendor:Ventana Plant ScienceRegular price $37.30 USDRegular priceUnit price / per -

Ventana Plant Science Isopropyl Alcohol ISO 99.9% 5-Gallon *HAZ*

Vendor:Ventana Plant ScienceRegular price $111.37 USDRegular priceUnit price / per -

Ventana Plant Science Isopropyl Alcohol ISO 99.9% 55-Gallon Drum *HAZ*

Vendor:Ventana Plant ScienceRegular price $799.16 USDRegular priceUnit price / per -

Hydrogen Peroxide Liquid Oxygen H2O2 34% 55 Gallon Bulk Drum

Vendor:Ventana Plant ScienceRegular price $460.66 USDRegular priceUnit price / per -

Hydrogen Peroxide Liquid Oxygen H2O2 34% 5-Gallon

Vendor:Ventana Plant ScienceRegular price $97.21 USDRegular priceUnit price / per -

Lowtemp V2 Rosin Press Medusa System (5 Press)

Vendor:LowTemp IndustriesRegular price $13,000.00 USDRegular priceUnit price / perLowtemp V2 Rosin Press Medusa System (5 Press)

Regular price $13,000.00 USDRegular priceUnit price / perLowtemp V2 Rosin Press Medusa System (5 Press)

Regular price $13,000.00 USDRegular priceUnit price / per -

Triminator Rosin TRP Stack

Vendor:TriminatorRegular price $5,980.00 USDRegular priceUnit price / per$5,980.00 USDSale price $5,980.00 USD -

Triminator Rosin TRP

Vendor:TriminatorRegular price $3,325.00 USDRegular priceUnit price / per$3,325.00 USDSale price $3,325.00 USD -

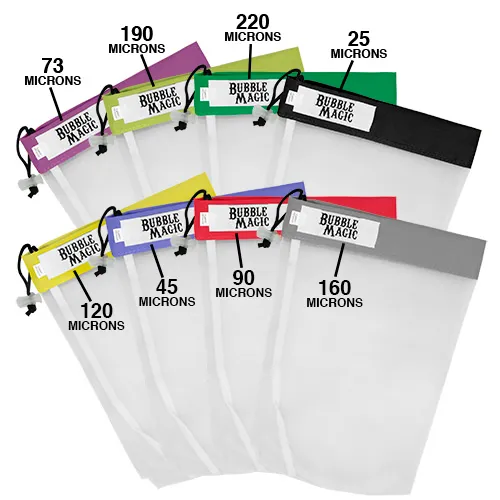

Bubble Magic All Mesh Extraction Bags 5 Gallon, 8 Bag Set

Vendor:Bubble MagicRegular price $109.92 USDRegular priceUnit price / per -

Bubble Magic All Mesh Extraction Bags 5 Gallon, 5 Bag Set

Vendor:Bubble MagicRegular price $70.58 USDRegular priceUnit price / per -

BVV 20LB ISO-BUTANE R600A - 99.5% Guaranteed High Purity USA

Vendor:BVVRegular price $134.00 USDRegular priceUnit price / per -

BVV 20LB PROPANE R290 - 99.5% Guaranteed High Purity USA

Vendor:BVVRegular price $154.40 USDRegular priceUnit price / per -

Bubble Magic Extraction Bags 5 Bag Set - 5 Gallon

Vendor:Bubble MagicRegular price $88.92 USDRegular priceUnit price / per -

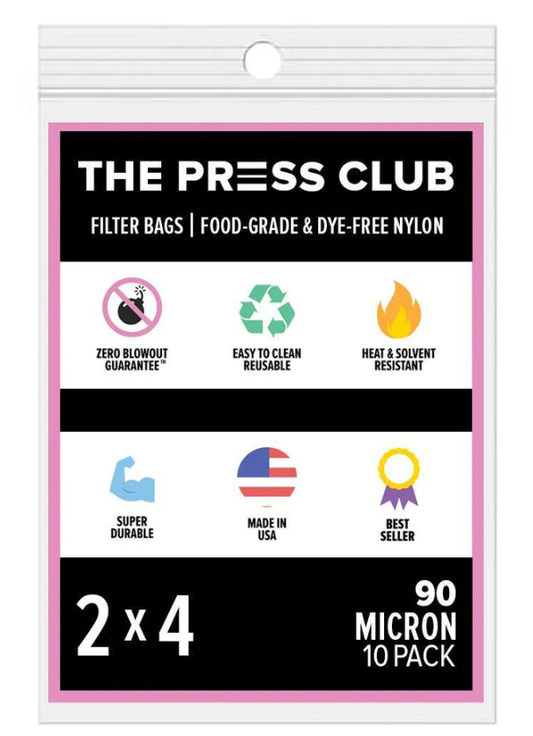

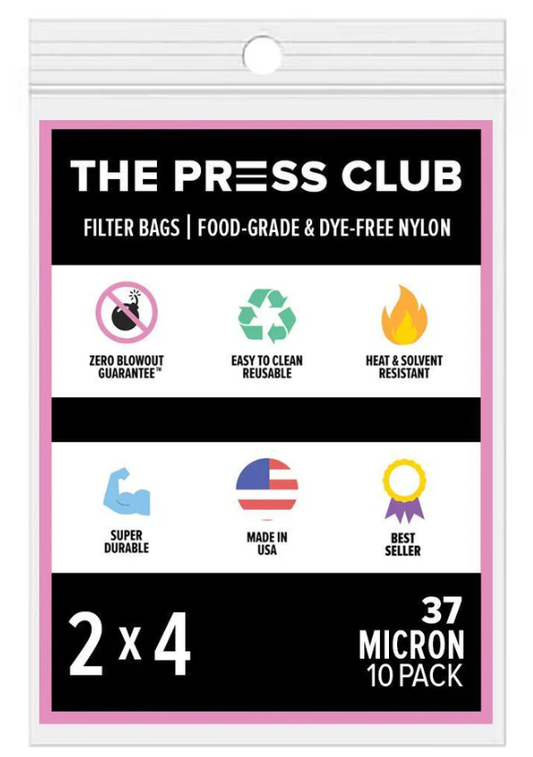

The Press Club 2" x 4" ROSIN BAGS (10 pack - 20 pack)

Vendor:The Press ClubRegular price From $12.95 USDRegular priceUnit price / perThe Press Club 2" x 4" ROSIN BAGS (10 pack - 20 pack)

Regular price From $12.95 USDRegular priceUnit price / perThe Press Club 2" x 4" ROSIN BAGS (10 pack - 20 pack)

Regular price From $12.95 USDRegular priceUnit price / per -

Bubble Magic All Mesh Extraction Bags 20 Gallon, 8 Bag Set

Vendor:Bubble MagicRegular price $184.38 USDRegular priceUnit price / per -

Harvest Right Freeze Dryer - Small - Black - With Mylar Starter Kit

Vendor:Harvest RightRegular price $2,295.00 USDRegular priceUnit price / per$2,395.00 USDSale price $2,295.00 USDSale

Extraction Equipment + Solvents

The Extraction Equipment + Solvents collection at GrowersHouse brings together professional extraction systems and high-purity solvents designed for essential oils, concentrates, and other botanical compounds from controlled-environment crops. Built for safety, repeatability, and throughput, these solutions help greenhouses, indoor farms, and processing labs turn harvested biomass into clean, stable, high-value extracts ...

Key Benefits for Growers & Processors

Moving from raw plant material to finished extract requires more than improvised labware. Purpose-built extraction equipment and correctly matched solvents control temperature, pressure, and contact time so you can target the compounds you want, limit impurities, and maintain consistent results batch after batch. Designed for modern agricultural processing, this collection supports both small pilot setups and full-scale facilities focused on quality and efficiency.

Higher Yield and Cleaner Extracts

Modern extraction systems and high-grade solvents pull more desirable oils and active botanical compounds from the same volume of biomass while reducing waxes and plant solids. This boosts yield per square foot and produces concentrates that are easier to refine, formulate, and package.

Safer, More Efficient Workflows

Closed-loop designs, recovery units, and compatible solvent handling components help reduce exposure risks, limit losses, and support compliance with safety guidelines. This makes it easier to maintain reliable, repeatable processing routines in busy grow operations and labs.

Scalable From Test Batches to Production

With options ranging from compact extraction units to larger, more automated systems, you can match your extraction setup to current demand and expand as your operation grows, without completely redesigning your process pipeline.

Main Uses of Extraction Equipment + Solvents

Growers and processors use this collection to extract essential oils and aromatic compounds from greenhouse and indoor crops, create concentrated inputs for tinctures, topicals, and infused products, and refine post-harvest output into consistent, branded extracts. It is especially useful where hydroponic or soilless systems produce uniform biomass that benefits from standardized downstream processing.

Types of Products in This Collection

- Extraction systems for ethanol, CO₂, and other solvent-based botanical extraction.

- Solvent handling and recovery equipment, including pumps, chillers, and recovery units.

- High-purity extraction solvents selected for performance and consistency.

- Filtration and post-processing components that help clarify, polish, and stabilize extracts.

Frequently Asked Questions

What solvents are used in essential oil extraction?

Common solvents include ethanol, supercritical CO₂, and selected hydrocarbon or specialty solvents approved for botanical processing. The right choice depends on your target compounds, safety requirements, and the extraction equipment you use, but ethanol and CO₂ are among the most widely adopted options for essential oils and similar extracts.

What is the best solvent for extraction?

There is no single best solvent for every application. Ethanol is a strong all-around choice due to its effectiveness, relative safety profile, and compatibility with large-scale systems. CO₂ is favored when precise tuning and minimal solvent residuals are priorities. The ideal solvent is the one that fits your target profile, regulatory framework, and equipment capabilities.

What equipment is used in extraction processes for hydroponic crops?

Typical setups combine biomass preparation tools (such as grinders or shredders), a dedicated extraction system (ethanol, CO₂, or another closed-loop unit), filtration hardware, solvent recovery equipment, chillers, and vacuum support. Together, this equipment transforms hydroponically grown plant material into concentrated, stable extracts that preserve the quality of your controlled-environment harvest.