Pre-Roll & Grinder Equipment

Upgrade your workflow with commercial pre-roll & grinder equipment built for high-volume production. Create uniform, perfectly packed cones while reducing labor and downtime in your dispensary or grow operation.

-

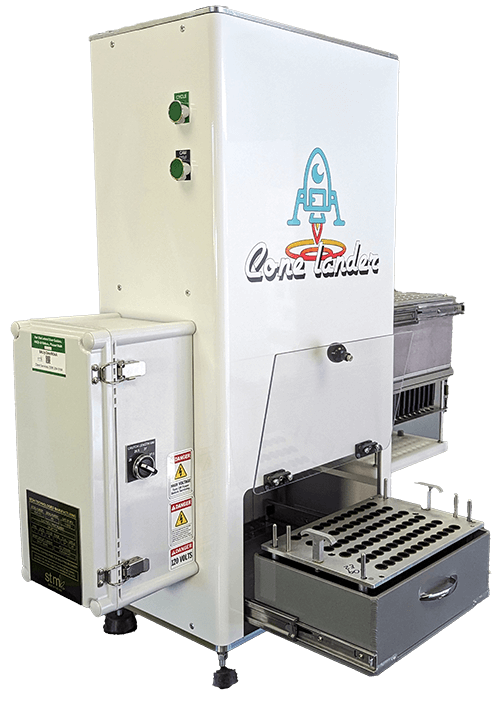

STM Canna Cone Lander Cone Loading Machine

Vendor:STM CannaRegular price $6,995.00 USDRegular priceUnit price / per$6,995.00 USDSale price $6,995.00 USD -

STM Canna - Dog Walker 72-Count Bottom Tray Starter Kit

Vendor:STM CannaRegular price $1,399.00 USDRegular priceUnit price / per -

STM Canna Harvest Package

Vendor:STM CannaRegular price $69,995.00 USDRegular priceUnit price / per$69,995.00 USDSale price $69,995.00 USD -

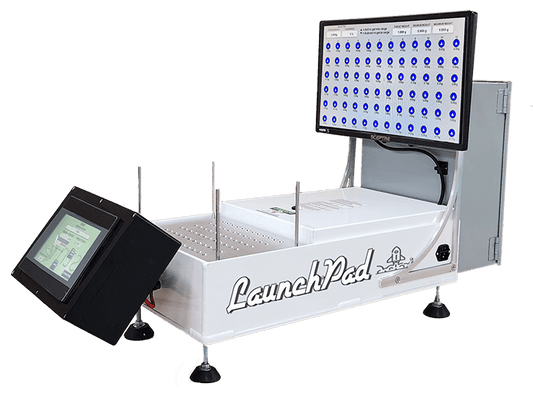

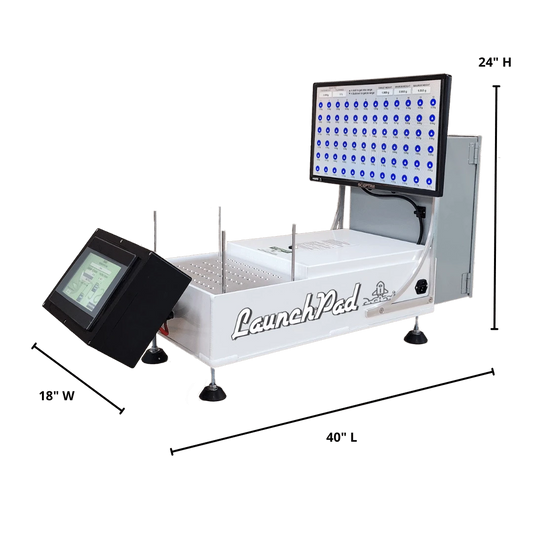

STM LaunchPad Weighing Module

Vendor:STM CannaRegular price $42,995.00 USDRegular priceUnit price / per$42,995.00 USDSale price $42,995.00 USD -

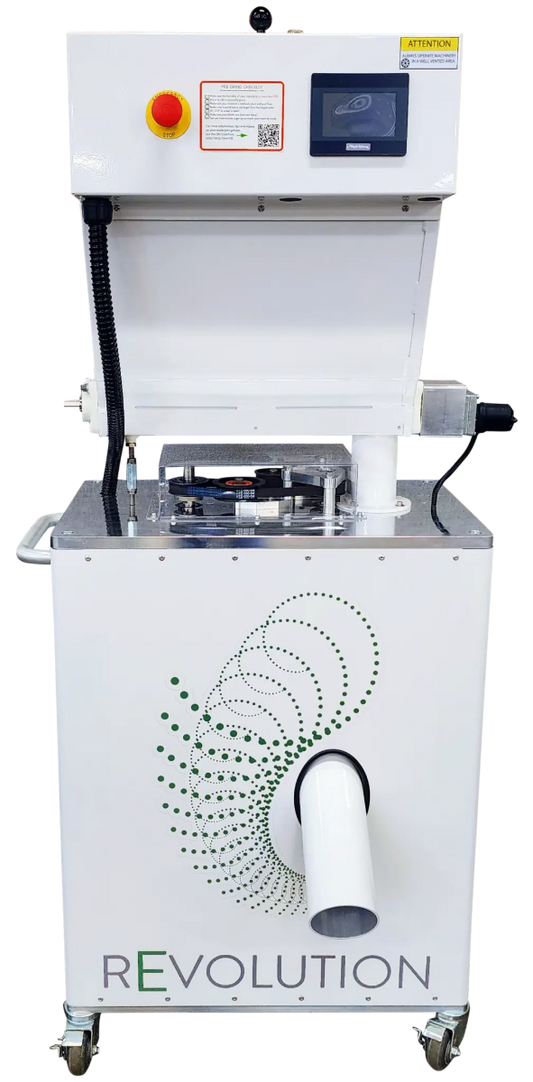

STM Mini-Revolution Commercial Flower Grinder

Vendor:STM CannaRegular price $6,600.00 USDRegular priceUnit price / per$6,600.00 USDSale price $6,600.00 USD -

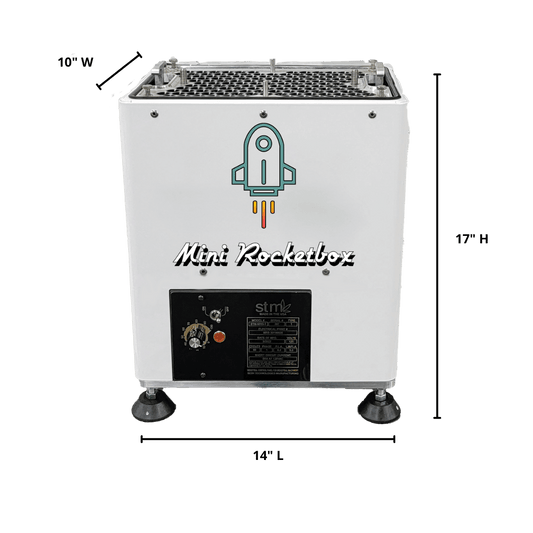

STM Mini-RocketBox PLUS+ Pre-Roll Machine (72-Joint)

Vendor:STM CannaRegular price $6,600.00 USDRegular priceUnit price / per$6,600.00 USDSale price $6,600.00 USDSTM Mini-RocketBox PLUS+ Pre-Roll Machine (72-Joint)

Regular price $6,600.00 USDRegular priceUnit price / per$6,600.00 USDSale price $6,600.00 USDSTM Mini-RocketBox PLUS+ Pre-Roll Machine (72-Joint)

Regular price $6,600.00 USDRegular priceUnit price / per$6,600.00 USDSale price $6,600.00 USD -

STM Revolution 2.0 commercial grinder

Vendor:STM CannaRegular price $22,950.00 USDRegular priceUnit price / per$22,950.00 USDSale price $22,950.00 USD -

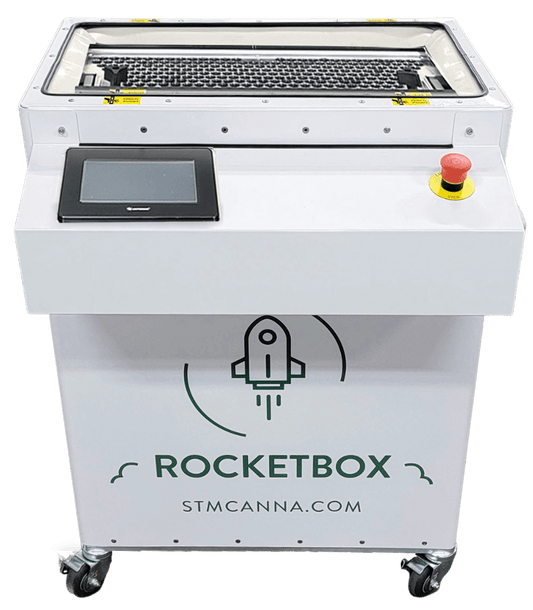

STM RocketBox 2.0 Pre-Roll Machine

Vendor:STM CannaRegular price $24,950.00 USDRegular priceUnit price / per$24,950.00 USDSale price $24,950.00 USD -

STM RocketBox PRO High-Output Pre-Roll Machine

Vendor:STM CannaRegular price $59,950.00 USDRegular priceUnit price / per$59,950.00 USDSale price $59,950.00 USD -

STM Mini-RocketBox PLUS+ Pre-Rolled Cone Filling Machine

Vendor:STM CannaRegular price $6,600.00 USDRegular priceUnit price / per$6,600.00 USDSale price $6,600.00 USDSTM Mini-RocketBox PLUS+ Pre-Rolled Cone Filling Machine

Regular price $6,600.00 USDRegular priceUnit price / per$6,600.00 USDSale price $6,600.00 USDSTM Mini-RocketBox PLUS+ Pre-Rolled Cone Filling Machine

Regular price $6,600.00 USDRegular priceUnit price / per$6,600.00 USDSale price $6,600.00 USD -

Futurola Dutch Crown Device

Vendor:FuturolaRegular price $1,875.00 USDRegular priceUnit price / per$1,875.00 USDSale price $1,875.00 USD -

Futurola - KB100 FATBOY - FILING DEVICE [FIXED]

Vendor:FuturolaRegular price $1,436.25 USDRegular priceUnit price / per -

Futurola - KB100 PARTY - FILING DEVICE [FIXED]

Vendor:FuturolaRegular price $1,436.25 USDRegular priceUnit price / per -

Futurola - KB100 REEFER / SLENDER - FILING DEVICE [FIXED]

Vendor:FuturolaRegular price $1,436.25 USDRegular priceUnit price / per -

Futurola - KB300 FATBOY - FIXED - FILLING DEVICE

Vendor:FuturolaRegular price $1,518.75 USDRegular priceUnit price / per -

Futurola - KB300 REEFER / SLENDER - FILLING DEVICE [FIXED]

Vendor:FuturolaRegular price $1,518.75 USDRegular priceUnit price / per

Pre-Roll & Grinder Equipment

Commercial Pre-Roll & Grinder Equipment for High-Volume Production

Streamline your operation with commercial pre-roll machines and flower grinders designed for serious production. This pre-roll & grinder equipment collection helps dispensaries and growers cut labor costs, increase daily output, and deliver consistent, perfectly packed cones that keep customers coming back...

Why Choose Commercial Pre-Roll & Grinder Equipment?

Manual rolling and hand-grinding take time, create bottlenecks, and often lead to inconsistent results. Commercial pre-roll machines and professional flower grinders automate the most repetitive tasks in your workflow, letting your team focus on quality control and customer service. With the right pre-roll grinder equipment, you can standardize grind size, fill cones evenly, reduce waste, and achieve predictable yields on every batch.

Types of Pre-Roll & Grinder Equipment

Pre-Roll Filling Machines

Pre-roll filling machines are engineered to load multiple cones at once with uniform density. Adjustable vibration and tamping settings help you dial in how tightly each cone is packed, minimizing loose draws or canoeing. These machines are ideal for dispensaries and growers that need reliable, repeatable pre-roll production every day.

Automated Pre-Roll Systems

For higher-volume operations, automated pre-roll systems can handle tray loading, filling, packing, and in some cases even twisting, with minimal manual intervention. This level of automation not only speeds up production but also helps with batch tracking, consistency across SKUs, and easier staff training.

Commercial Flower Grinders

Commercial flower grinders are designed to process bulk material quickly without overheating or over-pulverizing it. Consistent particle size is critical for even burning pre-rolls, so these grinders often include interchangeable screens or plates, safety interlocks, and easy-to-clean components that support hygienic, GMP-friendly workflows.

Integrated Grinding and Filling Workflows

When your grinder and pre-roll machines are properly matched, you create a smooth, end-to-end workflow: bulk flower in, finished pre-rolls out. This integration helps reduce material loss, avoid clogs and irregular fills, and makes it easier to scale from small-batch production to large, continuous runs as demand grows.

How This Equipment Helps Growers and Dispensaries

Upgrading to professional pre-roll & grinder equipment has direct impact on your bottom line. Automated systems reduce the number of staff needed on the line, and their speed boosts daily cone output, helping you meet wholesale orders or retail demand more easily. Consistent fills result in fewer customer complaints and returns, while precise grinding preserves aroma and structure for a better smoking experience. Overall, the right equipment makes your operation more efficient, more compliant, and more scalable.

Frequently Asked Questions

How many pre-rolls can a machine make?

Production capacity depends on the specific model and how your workflow is set up. Entry-level pre-roll machines can typically produce a few hundred cones per hour, while larger commercial units and automated systems may handle 1,000–3,000+ pre-rolls per hour with a trained operator. When choosing a machine, consider your current daily demand and your growth projections so you invest in equipment that can scale with your business.

What precautions should be taken when using a grinder machine?

Always follow the manufacturer’s instructions before operating a grinder. Common precautions include keeping hands and loose clothing away from moving parts, ensuring all guards and safety covers are in place, and never bypassing safety switches. Make sure the grinder is on a stable surface, check that the power supply is appropriate, and clean the equipment regularly with approved tools to prevent buildup. Providing staff with basic safety training and PPE, such as eye protection and masks where needed, is strongly recommended.

What are the OSHA requirements for using a grinder?

OSHA requirements can vary depending on the type of grinder and workplace, but they generally focus on machine guarding, proper electrical setup, safe operating procedures, and employee training. Employers are responsible for ensuring that grinders are equipped with appropriate guards, that staff are trained on safe use, and that personal protective equipment is used where necessary. For detailed and up-to-date guidance, review current OSHA standards and consult a safety professional familiar with your local regulations and facility layout.

![Futurola - KB100 PARTY - FILING DEVICE [FIXED]](http://growershouse.com/cdn/shop/files/futurola-kb100-party-filing-device.png?v=1735347763&width=533)

![Futurola - KB100 REEFER / SLENDER - FILING DEVICE [FIXED] Main Image](http://growershouse.com/cdn/shop/files/futurola-kb100-reefer-slender-filing-device.png?v=1735347766&width=533)

![Futurola - KB300 REEFER / SLENDER - FILLING DEVICE [FIXED] Main Image](http://growershouse.com/cdn/shop/files/futurola-kb300-reefer-slender-fixed-filling-device.png?v=1735347769&width=533)